Digital twin using a QR code

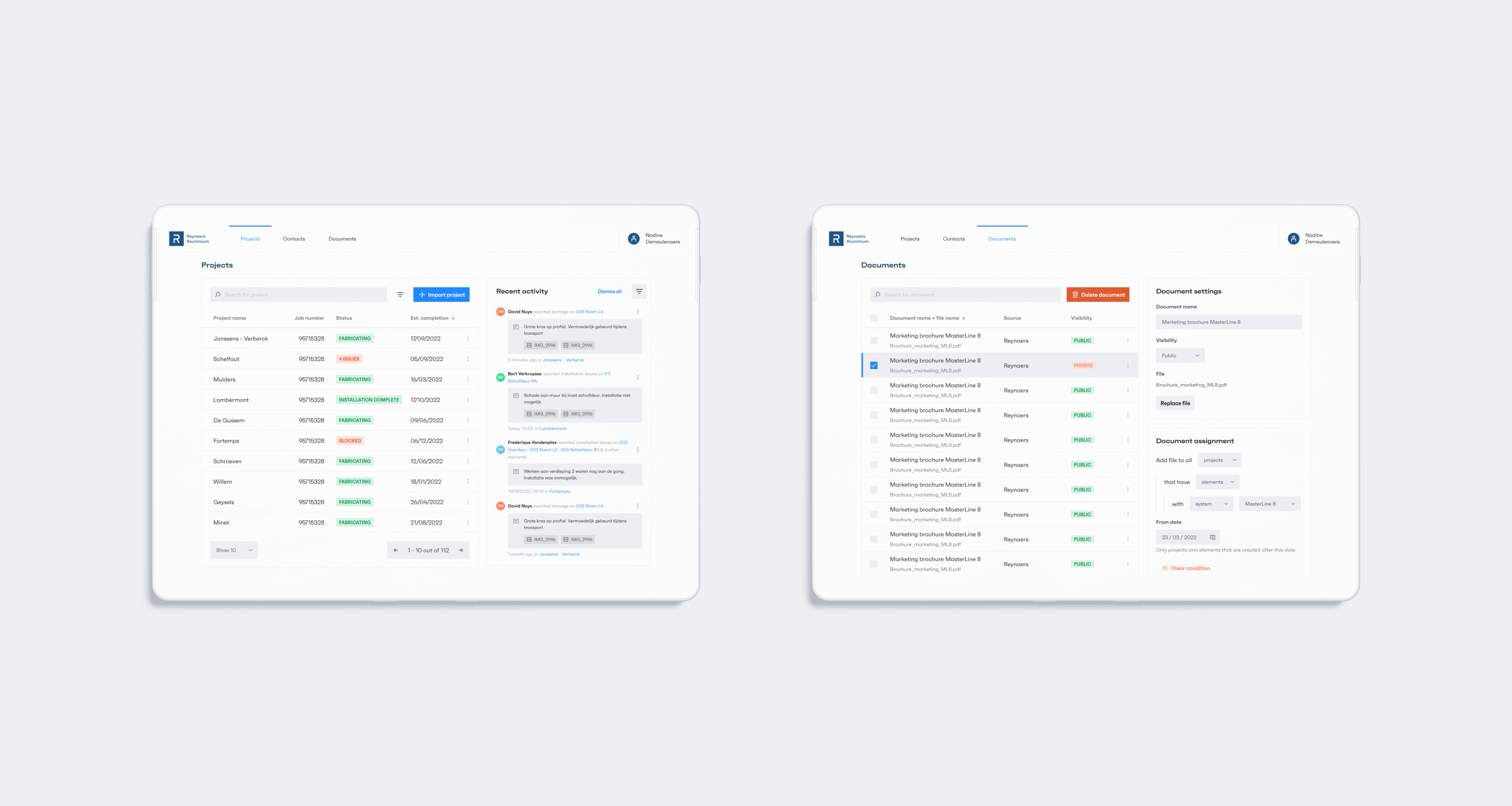

Reynaers already toyed with the idea of using a QR code on its aluminum frames containing a digital passport. Think of a digital twin that records all the information during the product’s entire lifetime: the fabricator’s details, the installers’ names, the type of system, the dimensions and color codes, and the maintenance instructions. We further investigated using a QR code, mapped all the user journeys (there were many) of all the stakeholders and set up the information architecture and workflow.

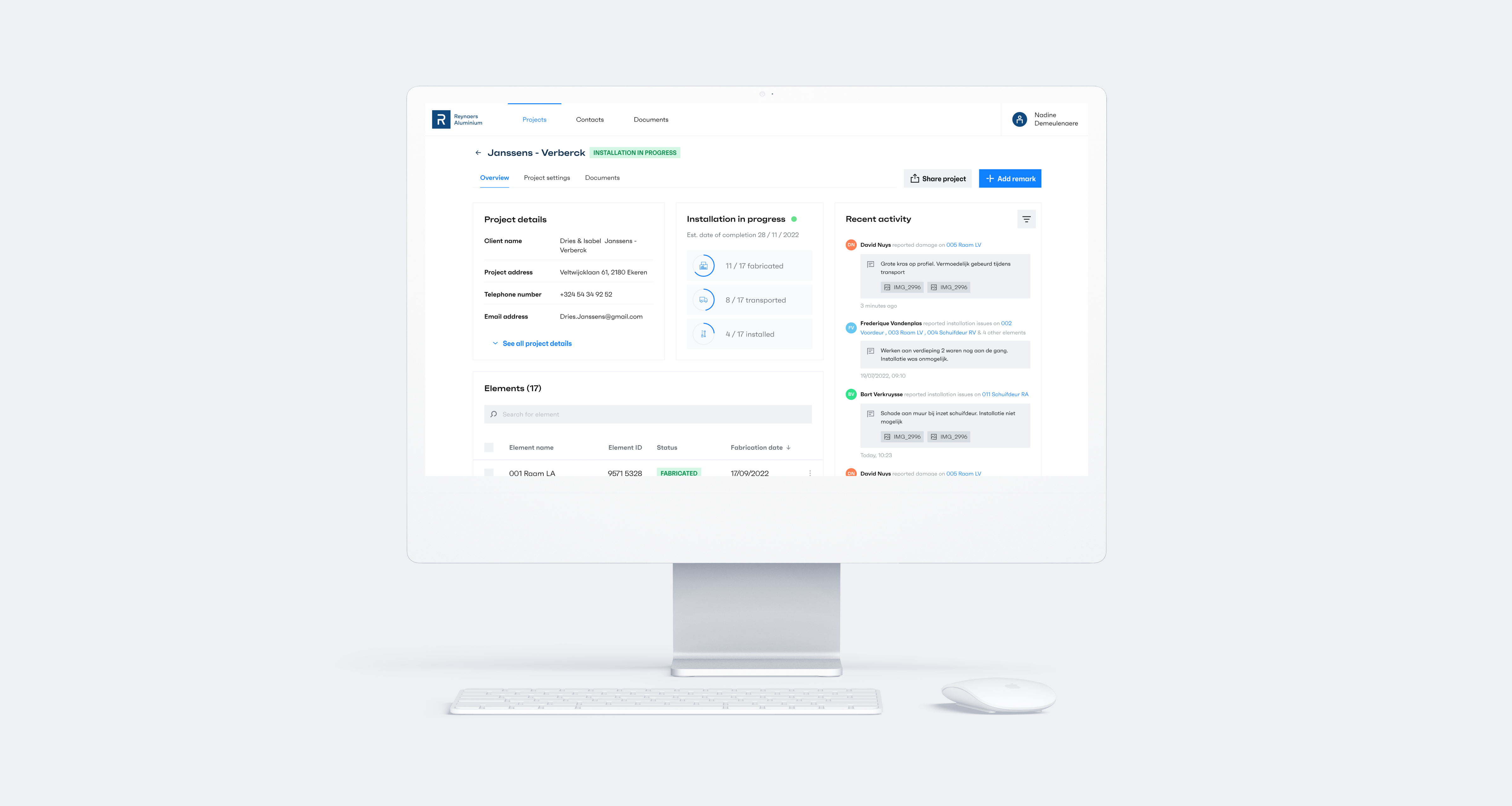

How it works

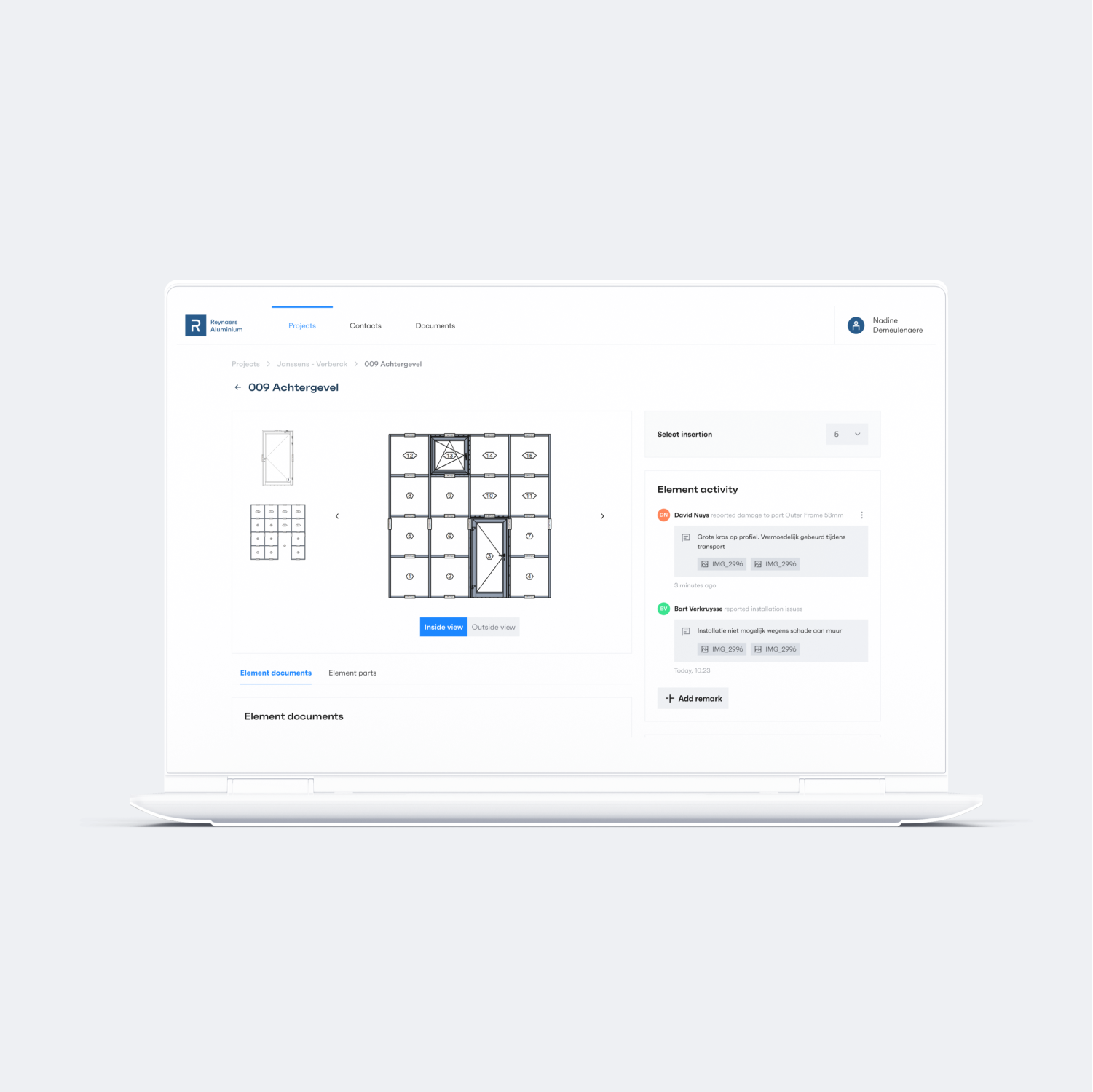

When Reynaers ships its aluminum profiles to the manufacturer who turns it into windows and doors, the latter attaches a QR code to it. Manufacturers first make an export of the project in the CPQ tool, ReynaPro. Then import it again in DigiTrace. DigiTrace is an online platform containing all information on the client and the project. They subsequently scan the QR code. Finally, they send the information of the scanned profile to the DigiTrace platform using the element linking app.

The benefits in a nutshell

Thanks to DigiTrace, homeowners can now retrieve information on who manufactured and installed their windows and doors. Fabricators can act fast because they can easily access that same information and share important documents with customers or other stakeholders. And installers can scan the code to be guided through the installation process. For Reynaers, the added value is the insights that help improve their products and services. In a later phase, production leaders will also be able to check the delivery state of their profiles.