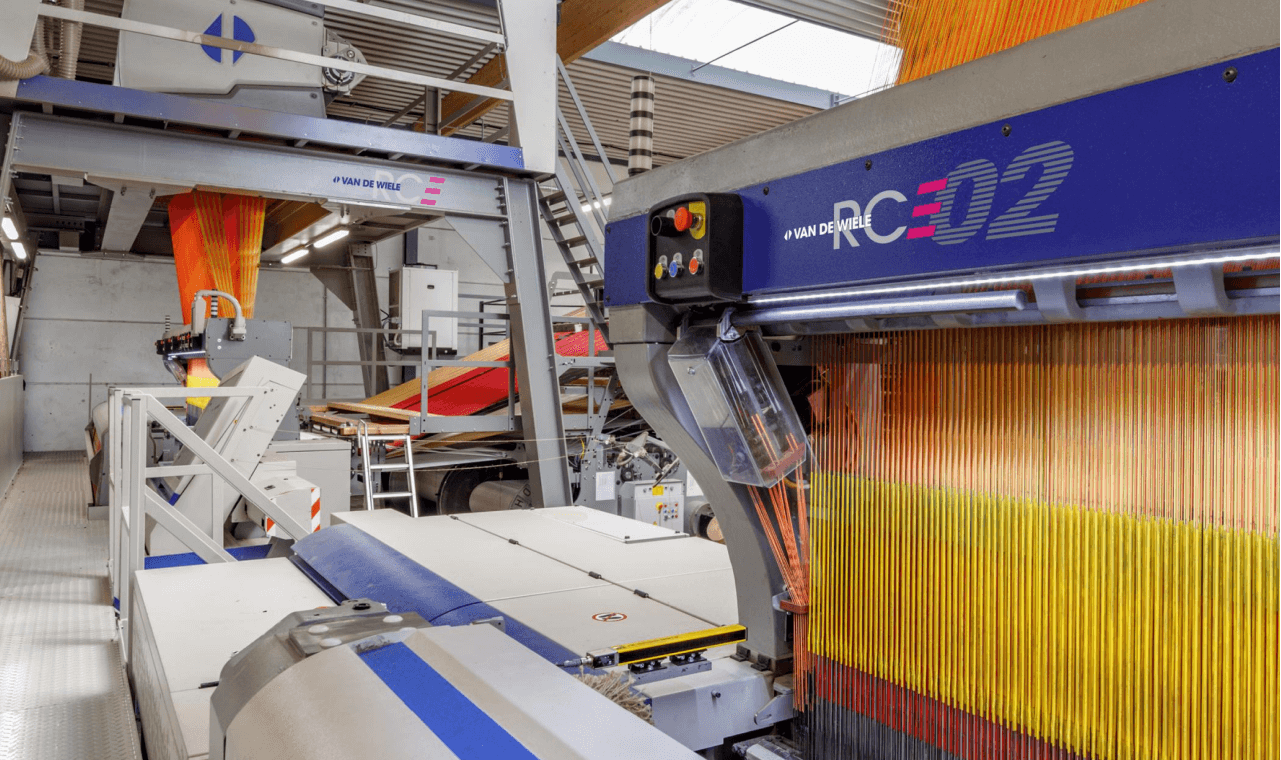

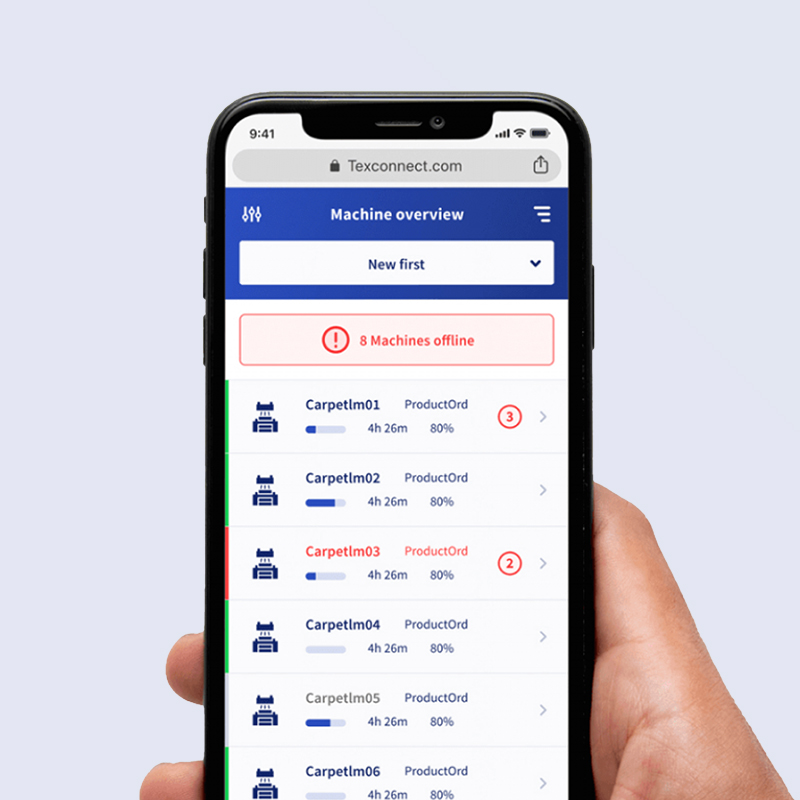

Enter TexConnect, a user-friendly hybrid cloud application (SaaS) aiming to enable their customers’ on-premise machinery to be managed and controlled from any system that is connected to the internet, and relieving Vandewiele from the deployment and maintenance burden of its predecessor.

Submerging ourselves in the quite complex domain of the weaving industry with several event-storming sessions, we gradually built an initial backlog of user stories, used as conversation starters for building minimal versions of new solutions during the first couple of iterations.

Initially, we focused on enabling production planners and managers to set up and maintain reusable textile data building blocks, which are all the things that are needed before being able to start creating actual production orders. Ranging from a simple yarn with its color and fabric, to the complex definitions of how a carpet needs to be finished further along the processing line or the huge creels that feed the weaving looms.

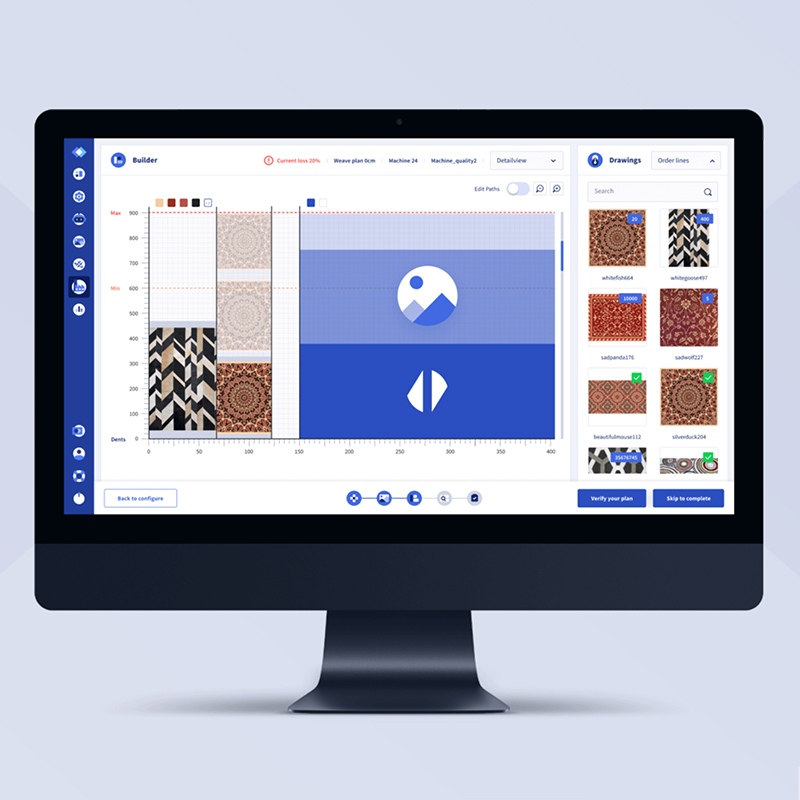

With a first version of those in place and tools for managing a library of designs and machines, the first steps towards a new way of building and planning production schedules, a giant puzzle of carpets that is eventually produced by the loom, are gradually being realized.