Following the trend of creating product ecosystems based on appliances, AB InBev and Philips teamed up to develop the first version of the PerfectDraft. This first generation offered basic functionalities with a metal keg and a keep-cool function for temperate or sub-polar conditions.

But to conquer the world, an upgrade was in order. AB InBev wanted to connect the PerfectDraft to collect data on consumer behavior: how and when people use the machine, user preferences for a metal keg or a crate of beer, regional differences in consumption, machine performance, etc. This would allow for predictive maintenance and improved customer service. Think about notifications of expiry dates and customized promotions. It would also offer AB InBev a platform to build a community.

So what was on the wish list for the PerfectDraft Pro?:

- Keg flexibility: accommodate the existing metal kegs as well as the new proprietary Puredraught one-way kegs (as unfortunately, some countries do not have a deposit system for metal kegs)

- Better cooling

- An improved and superior draught experience

- Usage and machine performance data

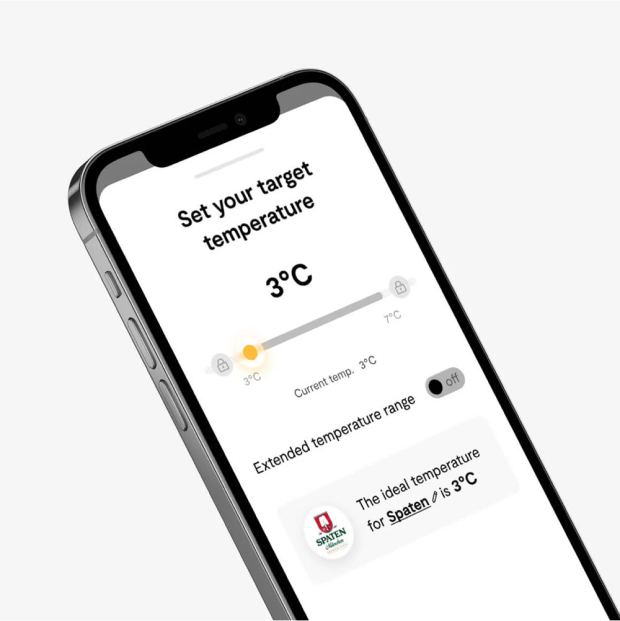

- Customizable temperature settings from 0° to 12°, to enable a better experience for more types and brands

- An eco mode to preserve the beer at a higher temperature when out of use

- A fully scalable IoT product

In short, it had to become the best beer-at-home pouring system the world had ever seen.

We started with design research. What about using a single bigger door instead of two smaller ones? In the first version, the keg also rests on a cooling plate causing a more local cooling. What if we would suspend the keg in a type of mini fridge? This would cause a more diffused cooling. We designed the new appliance and validated it with users. Thanks to a long history in R&D tracks for previous innovations, we could draw from extensive expertise built up throughout the years.

After the physical product was designed, it was time to connect it to the cloud to start collecting valuable data.

No beer without chips

There were numerous challenges. First of all, covid came and the world ran out of chips. Not only chips but also pumps and other parts. This made the hardware development particularly tricky. Every firmware version had to be compatible with every hardware version and the OTA (over-the-air) firmware update functionality thus became even more important than it already was.

Balancing data and user benefits

One of the biggest questions remained: what to measure? Numbers on alcohol consumption are sensitive information. At the same time, the data needs to be concrete enough to generate useful insights. You can also measure just about anything but this data needs to be weighed against the cost. Sensors don’t come cheap. And sending detailed information to the cloud every time somebody taps beer would be a costly affair.

On the other hand, all this data creates benefits for the user. How easy would it be if the PerfectDraft sent you a notification before you ran out of beer? Or before the beer expires? And what if customer service would call you up to replace a part before it breaks down? Timely orders, reduced waste, better customer service, predictive maintenance, monitoring usage create many advantages. It was a challenging walk on the tightrope of deciding which data to collect and send to the cloud. Anonymized of course.

The biggest challenge by far however, was project management. All our departments were involved, from strategic innovation to hardware, software, product design and market research. Throw in AB InBev’s branches from legal to marketing, sales and product development and you get an inkling of the complexity. Each department with its own goals and priorities of course. It was a monstrously sized project. Only carefully planned project management would get us to the finish line.

One last step in the process but crucial to its success, was finding the right manufacturer. We set up quality procedures together with AB InBev, delivered solid firmware, implemented final product improvements and helped set up the production lines. The only problem was covid. China was in total lockdown during the pandemic. We were therefore forced to manage the assembly process from a distance. Difficult but not impossible.